| Availability: | |

|---|---|

| Quantity: | |

SMARTELL

8419899090

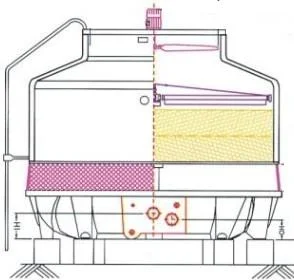

30T Cooling Tower for Plastic Injection Molding Machine

Features:

1. Panel: FRP material, smooth and beautiful surface, corrosion-resistant and anti-aging;

2. Filler: It is a modified polyvinyl chloride two-way point wave plate, with good thermal performance, small air flow assistance, good rigidity, heat resistant of 75℃,cold resistant and flame retardant.

3. Fan: The blade is made of alloy aluminum plate. The fan has the characteristic of reasonable aerodynamic force, large air volume, high efficiency, low noise and corrosion resistance.

4. Motor and reducer: Subcontract equipment.

5. Water distribution tank: FRP material, uniform water distribution, ultra-low noise type has a cover plate to block light, prevent debris from flying in, and reduce splashing sound.

6. Muffler cover: FRP material, internally glued cavity type flame retardant polyvinyl chloride thin muffler material.

7. Shutters: made of glass fiber reinforced plastic. can be splashed out and can make the air flow into the tower uniform.

8. Water tank: made of glass fiber reinforced plastic, which plays a role of water collection, Is equipped with automatic water replenishment facilities. and can directly absorb water in a closed loop.

9. Skeleton: It is a folded- edge steel assembly structure, with good rigidity,light weight, convenient transportation and installation. and hot-dip galvanized anti-corrosion.

Model number | - | 30T |

Water flow rate | M³/Hour | 23.4 |

Fan | CMM | 230 |

Basin diameter | MM | 1650 |

Height | MM | 1845 |

Fan diameter | MM | 770 |

Motor power | KW | 0.75 |

Water inlet and outlet | MM | 80 |

Water drainage | MM | 25 |

Water overflow | MM | 25 |

Water recharging | MM | 15 |

Net weight | KGS | 135 |

Running Weight | KGS | 550 |

DBA | - | 53 |

Voltage | V | 380 |

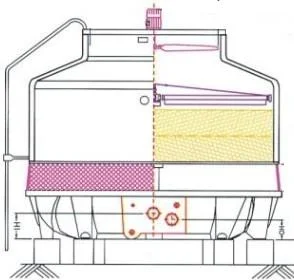

30T Cooling Tower for Plastic Injection Molding Machine

Features:

1. Panel: FRP material, smooth and beautiful surface, corrosion-resistant and anti-aging;

2. Filler: It is a modified polyvinyl chloride two-way point wave plate, with good thermal performance, small air flow assistance, good rigidity, heat resistant of 75℃,cold resistant and flame retardant.

3. Fan: The blade is made of alloy aluminum plate. The fan has the characteristic of reasonable aerodynamic force, large air volume, high efficiency, low noise and corrosion resistance.

4. Motor and reducer: Subcontract equipment.

5. Water distribution tank: FRP material, uniform water distribution, ultra-low noise type has a cover plate to block light, prevent debris from flying in, and reduce splashing sound.

6. Muffler cover: FRP material, internally glued cavity type flame retardant polyvinyl chloride thin muffler material.

7. Shutters: made of glass fiber reinforced plastic. can be splashed out and can make the air flow into the tower uniform.

8. Water tank: made of glass fiber reinforced plastic, which plays a role of water collection, Is equipped with automatic water replenishment facilities. and can directly absorb water in a closed loop.

9. Skeleton: It is a folded- edge steel assembly structure, with good rigidity,light weight, convenient transportation and installation. and hot-dip galvanized anti-corrosion.

Model number | - | 30T |

Water flow rate | M³/Hour | 23.4 |

Fan | CMM | 230 |

Basin diameter | MM | 1650 |

Height | MM | 1845 |

Fan diameter | MM | 770 |

Motor power | KW | 0.75 |

Water inlet and outlet | MM | 80 |

Water drainage | MM | 25 |

Water overflow | MM | 25 |

Water recharging | MM | 15 |

Net weight | KGS | 135 |

Running Weight | KGS | 550 |

DBA | - | 53 |

Voltage | V | 380 |