| Syringe Size: | |

|---|---|

| Availability: | |

| Quantity: | |

SMT-3305

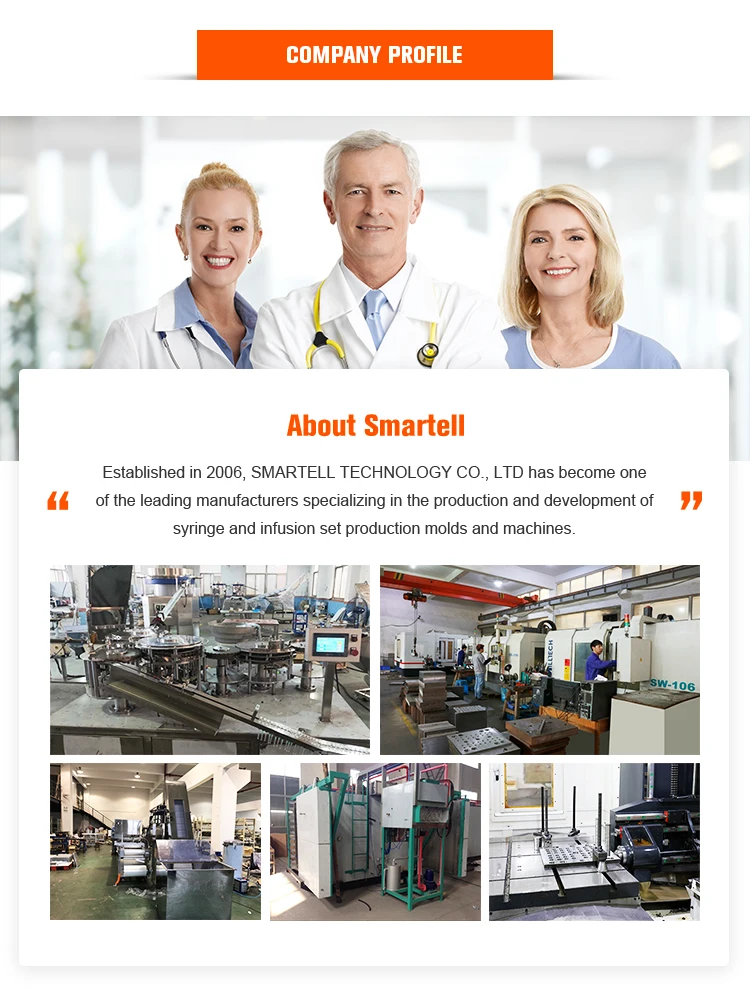

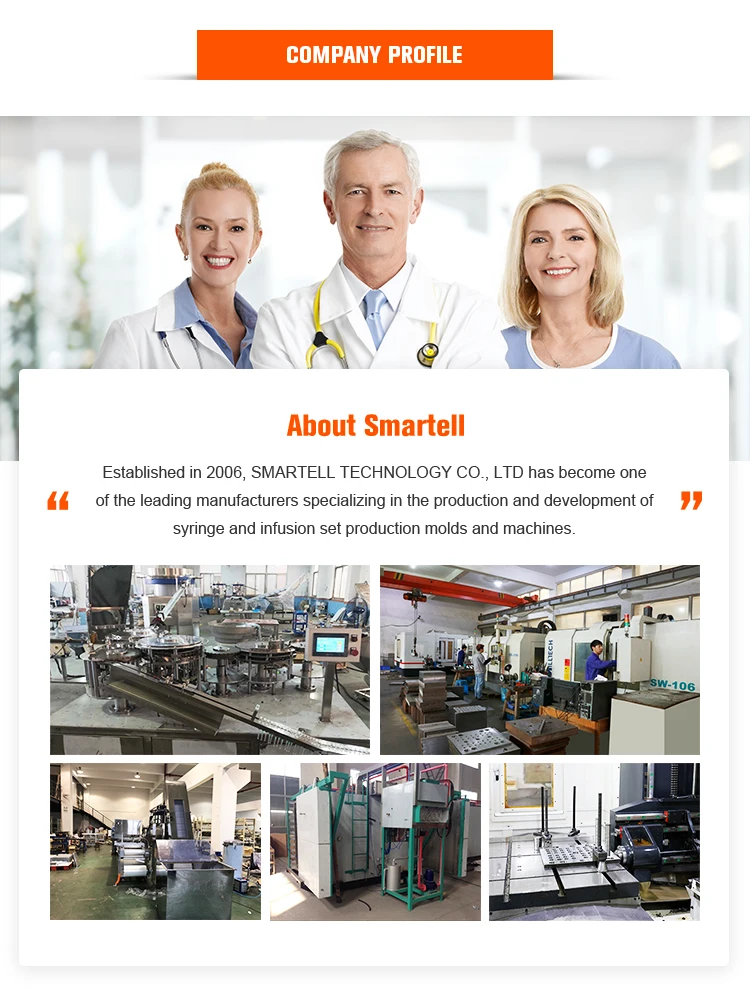

SMARTELL

8479899990

Disposable Syringe Automatic Assembly Machine

Three parts syringe: syringe barrel, syringe plunger and syringe gasket.

Assemble Syringes Types: luer lock, luer slip, central-nozzle and ex-central nozzle syringes with needle or without needle.

Machine Features:

--Controlled by touch screen: Automatically eliminate unqualified products and raw materials control.

--Stainless steel material, not easy to get rusty. Won't bring any pollution to syringe and cleaning workshop.

Advantages

1. Equipped with spray-oil device

2. High efficient production

3. Auto stop when lack of material, and auto start when supply material.

4. Easy operate control system

Production SPEC | Production Speed | Dimension | Weight | Power | Compressed air flow |

1ml | 180pcs/min | 4200x3000x2100 mm | 1500 kg | AC220V/3KW | 0.3m3/min |

2-3ml | 200pcs/min | ||||

5ml | 250pcs/min | ||||

10ml | 250pcs/min | ||||

20ml | 160pcs/min | ||||

30ml | 150pcs/min | ||||

50-60ml | 120pcs/min |

Governor system adopts Japan's Mitsubishi converter

This equipment adopts microcomputer control, uses Japanese Mitsubishi inverter for speed regulation. This machine is of low power consumption, photoelectric monitoring, idle self-stop, fast assembly speed, stable and reliable performance. It can automatically check the unqualified products, which greatly improves the quality of the products.

Advantages:

1) One-stop service : providing a complete range of equipment, material or technical services that customer might require for syringe production.

2) Our machine is of high efficiency and stability. Its technology and performance can reach international advanced level.

3) 20-year experience in designing, researching & developing, manufacturing the syringe equipment.

4) Professional sales team, providing 7x 24 hours service.

5) Overseas after-sales service, skilled engineers will go to install and debug the machine at buyer’s location.

6) Production manager's theoretical and practical training solution, or headhunting service.

Disposable Syringe Automatic Assembly Machine

Three parts syringe: syringe barrel, syringe plunger and syringe gasket.

Assemble Syringes Types: luer lock, luer slip, central-nozzle and ex-central nozzle syringes with needle or without needle.

Machine Features:

--Controlled by touch screen: Automatically eliminate unqualified products and raw materials control.

--Stainless steel material, not easy to get rusty. Won't bring any pollution to syringe and cleaning workshop.

Advantages

1. Equipped with spray-oil device

2. High efficient production

3. Auto stop when lack of material, and auto start when supply material.

4. Easy operate control system

Production SPEC | Production Speed | Dimension | Weight | Power | Compressed air flow |

1ml | 180pcs/min | 4200x3000x2100 mm | 1500 kg | AC220V/3KW | 0.3m3/min |

2-3ml | 200pcs/min | ||||

5ml | 250pcs/min | ||||

10ml | 250pcs/min | ||||

20ml | 160pcs/min | ||||

30ml | 150pcs/min | ||||

50-60ml | 120pcs/min |

Governor system adopts Japan's Mitsubishi converter

This equipment adopts microcomputer control, uses Japanese Mitsubishi inverter for speed regulation. This machine is of low power consumption, photoelectric monitoring, idle self-stop, fast assembly speed, stable and reliable performance. It can automatically check the unqualified products, which greatly improves the quality of the products.

Advantages:

1) One-stop service : providing a complete range of equipment, material or technical services that customer might require for syringe production.

2) Our machine is of high efficiency and stability. Its technology and performance can reach international advanced level.

3) 20-year experience in designing, researching & developing, manufacturing the syringe equipment.

4) Professional sales team, providing 7x 24 hours service.

5) Overseas after-sales service, skilled engineers will go to install and debug the machine at buyer’s location.

6) Production manager's theoretical and practical training solution, or headhunting service.